About Us

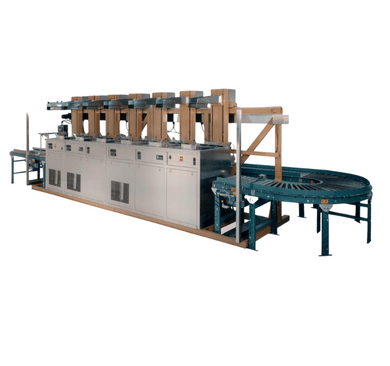

For nearly 60 years, our commitment to quality ultrasonic cleaning systems and customer service has earned us the trust and loyalty of thousands of satisfied customers worldwide. Sonicor’s ultrasonic cleaning systems have successfully addressed the critical cleaning systems requirements of leading companies in virtually every industry. This wealth of experience has provided our application and engineering staff members with the unique qualifications to meet the needs of our customers, as ultrasonic cleaning systems requirements become increasingly critical.